International Seminar Series on Programmable Materials

Event details

Location

Online via MS Teams

May 20, 2021

Programme

| DATE | sPEAKER | tOPIC / Title | Join Meeting |

|---|---|---|---|

| Thursday, 20 May 2021, 4 - 5.30 p.m. (CEST) | Prof. Dr. Dr.h.c. Peter Fratzl, Max Planck Institute of Colloids and Interfaces, Potsdam, Germany (webpage) | Local fibre orientations control the behaviour of biological materials | The talk has already taken place. |

| Thursday, 10 June 2021, 3 - 4.30 p.m. (CEST) | Prof. Dr. Thomas Speck, University of Freiburg, Germany (webpage) | Adaptive pre-programmed, interactive plant material systems and structures as models for novel technical developments | The talk has already taken place. |

| Thursday, 01 July 2021, 3 - 4.30 p.m. (CEST) | Prof. Caroline A. Ross, Massachusetts Institute of Technology, USA (webpage) | Programmable Nanostructures by Directed Self-assembly of Block Copolymers | The talk has already taken place. |

| Thursday, 2 September 2021, 1 - 2.30 p.m. (CEST) | Ph.D. Jean-Marie Raquez, Université de Mons, Belgium (webpage) | How the stereolithography technique can revolutionize the design of Soft Polymeric Materials for Multiple Purposes | The talk has already taken place. |

| Thursday, 14 October 2021, 3 - 4.30 p.m. (CEST) | Prof. Dr. Christoph Keplinger, Max Planck Institute for Intelligent Systems, Germany (webpage) |

HASEL Artificial Muscles - Versatile High-Performance Actuators for a New Generation of Lifelike Robots | The talk has already taken place. |

Agenda

- Welcome and short introduction by member of Fraunhofer CPM (c. 10 minutes)

- Talk (c. 45 minutes)

- Discussion (c. 35 minutes)

You are invited to take actively take part in the discussion. Please note that the talk itself will be recorded and used for internal purposes afterwards.

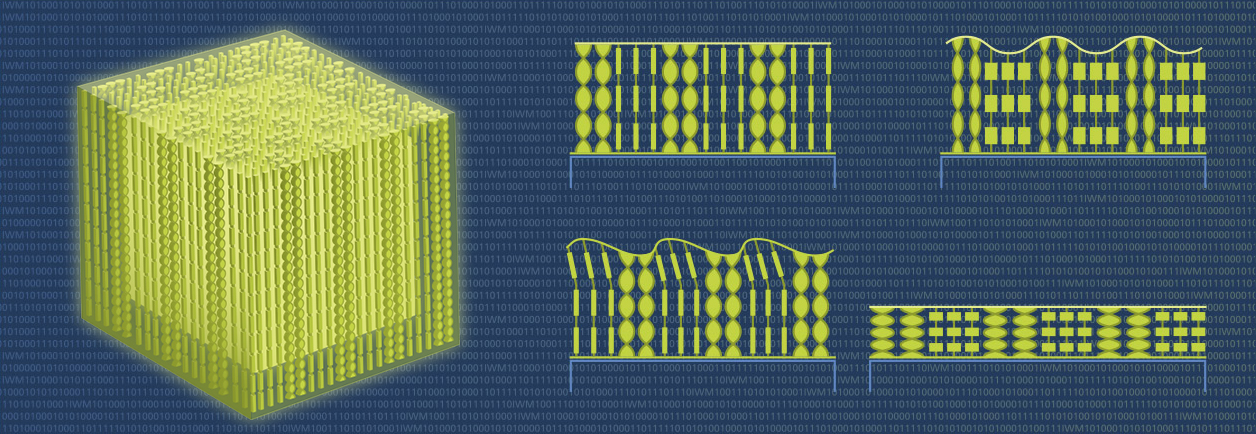

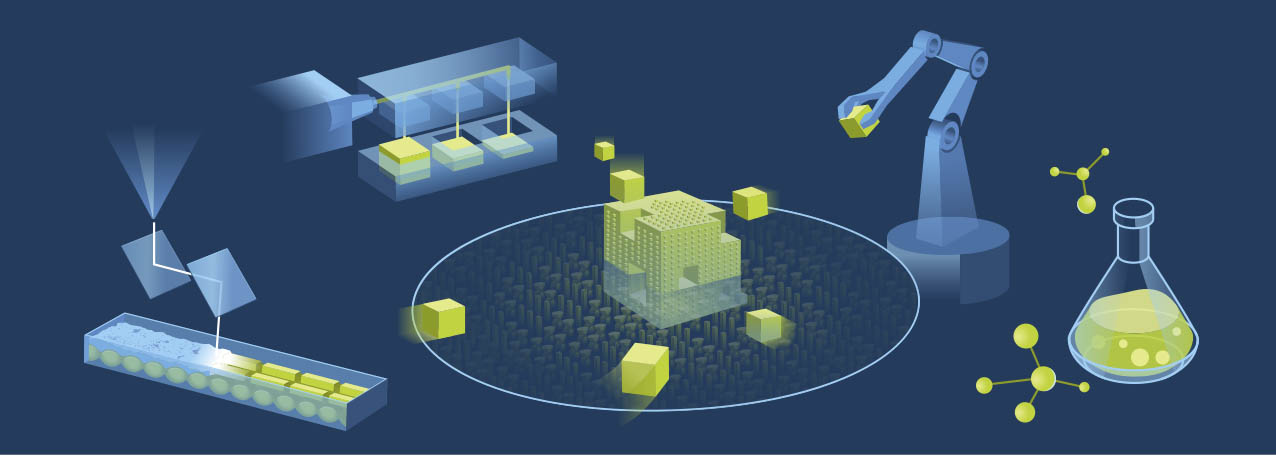

Programmable materials are materials or material compositions, which are structured such that their properties can be specifically controlled and reversibly changed. Complex and locally different functions can be programmed into these materials.

Depending on the application and situation, the material then adopts different conditions and material properties initiated by external triggers.

Programmed = fixed functionality programmed into material during fabrication

Programmable = adaption of function during application

Programmable materials introduce a unique potential for new system solutions because they themselves adopt important system functionalities, thus making additional system components such as sensors or actuators redundant.

Past talks

International Seminar / October 14, 2021

HASEL Artificial Muscles - Versatile High-Performance Actuators for a New Generation of Lifelike Robots

Prof. Dr. Christoph Keplinger, Max Planck Institute for Intelligent Systems, Germany

Event details

Location

Online via MS Teams

October 14, 2021

International Seminar / September 02, 2021

How the stereolithography technique can revolutionize the design of Soft Polymeric Materials for Multiple Purposes

Ph.D. Jean-Marie Raquez, Université de Mons, Belgium

Event details

Location

Online via MS Teams

September 02, 2021