Programmable material permeability

Motivation

“The good ones go into the pot, the bad ones go into your crop” - intelligent filter mechanisms are worth their weight in gold. Yet, the reality is different from the fable. Be it the gas filtration in white rooms or operation theatres to liquid filtration in the water treatment or the beverage industry, every form of industrial filtration faces two basic interconnected challenges: removal of the filtrated substances and minimization of the designated fouling deposits on the filter surface.

Tangential flow and dead-end filtration are two of the most frequently used filtration methods. While the former minimizes deposits by means of a flow direction transverse to the filter membrane, backwashing comes into play as a countermeasure to combat fouling in the latter. In this method, the pumps push the already cleaned solution back to the pre-filtration side in order to flush down the so-called filter cake from the filter. The disadvantage of the tangential flow is low energy efficiency because a large part of the energy invested in the transport of the feed gets lost in the fluid retained by the membrane and does not accelerate the filtration as desired. Backwashing is also inefficient, as it involves high energy costs and the cleaning step interrupts the production flow. According to estimates, the energy costs of filtration systems are up to 50% of the production costs, depending on the depreciation procedures.

Filter materials and membranes, which allow other properties such as flow parameters or release of active ingredients depending on the presence of deposits or biological foreign bodies, may initiate a radical change. In the light of the enormous potential of economic savings, the cluster of programmable materials is working on innovative methods for controlling and programming the permeability, selectivity and porosity of membranes.

Research topic and applications

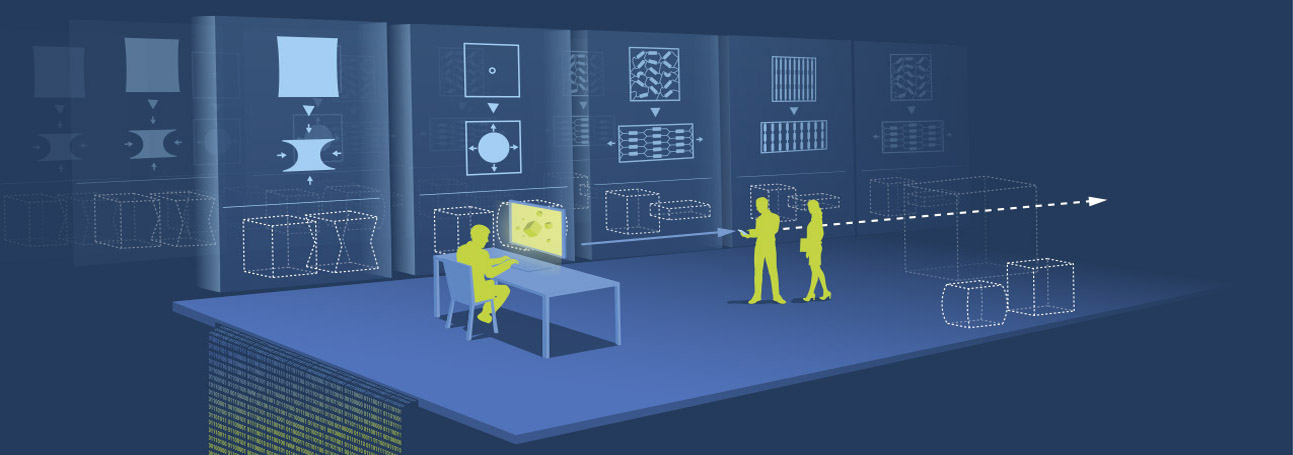

The institutes that are a part of the cluster focus on multiple approaches. Importance is given to the programmable control of geometry for influencing and optimizing currents and permeabilities. The activities of the focal topic of programmable substance permeability are diversified - from the use of unconventional polymers for manufacturing membranes, to pressure stability and permeance-optimized membrane morphologies, new methods against fouling on surfaces up to the building of a material and function library.

To improve the self-cleaning function of membranes, the researchers are investigating the introduction of vortex promoters into the structure of the membrane surfaces. These could be equipped with microcapsules such that they can specifically release substances that prevent the growth of microorganisms on the surface of the membrane. In cross-flow filtration, the particles induce vortices that generate a cleaning effect without increasing the energy consumption unfavorably.

Abrasion-proof shape-memory polymers on TPU basis can also be designed such that they are temperature-switchable. In case of membranes, switching the material may lead to an enlargement or shrinking of the pores due to a macroscopic geometric modification. Processes in which certain temperature ranges allow greater substance permeability may be conceptualized in this manner. The cluster also checks these functionalities for use in breathable clothing such as T-shirts, jackets or sport shoes. If the body heat increases, the pores of the membrane change so that there is an intensified air exchange. When the heat reduces, the pores close back again.

Another research topic of the cluster is the control of local chemistry for checking the diffusion ratio or the chemical composition of the filtrate.

For this, the participants investigate coatings with programmable polymers, which respond independently to chemical, biochemical and physical triggers. When the desired substance is bound to the membrane, it swells and closes its pores. Due to the lock-and-key principle, there are hardly any trigger-related limitations: pH-values, temperatures, salt or water contents or micro pollutants are possible even now and are already partly implemented in demonstrators. This solution is very promising in terms of the reduction of the complexities of systems as well as for material and resource efficiency, because shut-off devices, detectors or software would no longer be required.

At the moment, the researchers are building a material and function library from the focal topic in order to identify suitable triggers for corresponding applications. In the future, they also want to realize the combination of multiple triggers as a multilayered structure. Obvious applications with which the cluster is dealing are agricultural protective films and irrigation systems, whose lines open at a specific temperature.

The respective control or the locally programmed property change in the programmable hydrogel-membrane materials can likewise take place as a result of the actuator functionalities integrated in the material from external triggers such as temperature, pH-value or pressure.

In this case, the cluster relies on the use of the classic membrane material polyvinylidine fluoride (PVDF). Due to its strong dissemination, the process know-how is high and different membrane geometries can be produced on large scales.

Appropriately structured PVDF membranes begin to vibrate like a loudspeaker after the creation of an alternating electric field. This effect would lead to the shedding of deposits and thus to cleansing in the case of filter membranes. However, researchers in the cluster also see applications in completely different fields. Chemical reactions can be accelerated or intensified massively due to the reduction in the laminar flow on the surface of the membrane. Therefore, these membranes are very interesting for reaction and mixing processes in the chemical, pharmaceutical and food industries.

What are the current challenges?

The biggest challenge of the subject area of programmable material transport is the production-related implementation of materials on a larger scale.

Hydrogel membrane materials cannot as yet be produced in tons, but they are knife-coated on the membrane as a thin foil so that surfaces of up to 50 m2 can be coated with just a few hundred grams. This is the case even when the coatings are completely self-sufficient for some triggers such as temperature, biochemical triggers, water content and pH value. The bonding of sugar represents a very attractive application, because they are a very good indicator of many poisonous substances. So far, the covalent bond can only be made reversible by using cleaning substances. This is a topic that the cluster wants to deal with in the near future.

“A challenge regarding membranes within shape-memory polymers is faced in the production of materials that brings along the entire important range of properties and functionalities for an application. It is also important to develop a deeper understanding for two-way shape-memory effects in order to make application-specific optimizations in the synthesis and to be able to integrate perspective methods for thermo-mechanical treatment of shape-memory polymers in industrially established processes.”

The polymers could be programmed for suitable temperature ranges for the same. They could thus be used to adapt membranes for breathable clothing to temperature zones that are comfortable for humans. The membrane itself however still has a thickness of a few dozen micrometers and is therefore not really suitable for use in body-hugging clothing, unless you consider use for locally limited areas, e.g. under the armpits or on the back. However, use in sport shoes, for instance for the level above the instep appears to be promising.

Status: 26.07.2019

Publications

Referred journals

Neumann, Christian; Bacher, Lisa; Musyanovych, Anna; Tutus, Murat; Latnikova, Alexandra; Formulation of next-generation multicompartment microcapsules by reversible electrostatic attraction, Chemistry - A European Journal 27/36 (2021) 9336–9341

Link

Participating institutes of the cluster: IAP

Osterroth, Sebastian; Neumann, Christian; Weiß, Michael; Maurieschat, Uwe; Latnikova, Alexandra; Rief, Stefan; Effect of modifying the membrane surface with microcapsules on the flow Field for a cross-flow membrane setup: A CFD study, Membranes 11/8 (2021) Art. 555, 25 pp.

Link

Participating institutes of the cluster: ITWM, IAP, IFAM

Schönfeld, Dennis; Chalissery, Dilip; Wenz, Franziska; Specht, Marius; Eberl, Chris; Pretsch, Thorsten; Actuating shape memory polymer for thermoresponsive soft robotic gripper and programmable materials, Molecules 26/3 (2021) Art. 522, 20 pp.

Link

Participating institutes of the cluster: IAP, IWM

Chalissery, Dilip; Pretsch, Thorsten; Staub, Sarah; Andrä, Heiko, Additive manufacturing of information carriers based on shape memory polyester urethane, Polymers 11/6 (2019) 1005 1-19

Link

Participating institutes of the cluster: IAP, ITWM

Non-referred journals

Chalissery, Dilip; Pretsch, Thorsten; Staub, Sarah; Kasack, Katharina; Andrä, Heiko; 3D-Druck von QR-Codes mit Formgedächtniseigenschaften, Der Druckspiegel 11-12 (2019) 34-37

Link

Participating institutes of the cluster: IAP, ITWM, IZI BB

Lectures

Tröger-Müller, Steffen

Entwicklung von intelligenten und biobasierten Agrarfolien

Vom Feld in die Fabrik

virtuell, Deutschland; 23.06.2021

Tröger-Müller, Steffen

Programmierbare biobasierte Verpackungen

Industrie-Workshop Nestlé Innovation Center

virtuell, Deutschland; 16.03.2021

Staub, Sarah

Mikromechanische Simulation des effektiven Materialverhaltens von hochporösen Werkstoffen und Anwendung in Programmierbaren Materialien

ProMatLeben - 1. Doktoranden und Post-Doc Konferenz

Berlin, Deutschland; 03.09.2019-04.09.2019

PhD theses

Stefan Kluge

Universität Potsdam

Integration anorganischer Füllstoffe in Polysilfonmembranen und Auswirkungen auf die Gastransporteigenschaften

Bacher Lisa

Johannes Gutenberg-Universität in Mainz

Kontinuierliche Prozessentwicklung für die mikrofluidische Verkapselung von festen, flüssigen und leichtflüchtigen Substanzen als Kernmaterial

Students' theses (Bachelor, Master, Diploma)

Einfluss der Prozessierungsparameter auf die Permeationseigenschaften einer PAN-Membran (B)

Herstellung und Charakterisierung von Polyacrylnitril-Membranen unter Variation von Prozessparametern (B)

New programming approaches for shape memory polymers (M)

Neuartige Formgedächtnispolymermaterialien für Membrananwendungen (M)

Optimization of poly (1,4-butylene adipate) synthesis using different catalysts and utilization for shape-memory polyurethane synthesis (M)

Synthesis of polystyrene microparticles via radical polymerization for the controlled delivery of active components (M)

Posters

Neumann, Christian

Control of functional groups on microcapsule/particle surface through novel coating approach

Jahrestreffen der ProcessNet-Fachgruppen Lebensmittelverfahrenstechnik, Mischvorgänge, Grenzflächenbestimmte

Systeme und Prozesse 2021

virtuell, Deutschland; 11.03.2021-12.03.2021

Neumann, Christian

Programmable Materials – Use of microcapsules

7. Workshop Technologieplattform Mikroverkapselung 2019

Bremen, Deutschland; 23.10.2019-24.10.2019