Manufacturing and upscaling

Motivation

Targeted changes in the material properties or in the shape of the components in technical applications may radically revolutionize industrial products and production technologies. In particular, materials with programmed stiffness or situational shape change could provide new functionalities such as system-adapted stiffness to products or make them more individual due to their adaptivity, while simultaneously cutting down on assembly, storage and logistical costs. For these reasons, their application predicts a very high market volume, e.g. in fail-safe robot structures for human-computer-interaction or in the field of vehicle bumpers. Another interesting field of application is active aerodynamics, wherein all types of road vehicles and rail cars, ships and aircrafts, pumps or wind turbines can minimize or maximize their drag by changing their shape, relative to the operating conditions.

The transfer of mostly nanoscale and microscale approaches for programming materials at the macroscale component level requires production technologies that enable efficient production of functionally integrated materials. It can also be anticipated that in the future not only one property will be programmed in assemblies and systems, but that components and modules will generally require different functions. Due to this, the technological approaches for producing materials and parts must be flexible enough to produce components with locally different functional elements. Moreover, the designing of complex macroscopic components that completely consist of microscale programmable structures are not practical from the economic point of view, resulting in the need for innovative solutions. As of yet, the research has no satisfying answers to these challenges. Conceivable approaches are concepts that make use of self-organization, the development of claytronics or the integration of Smart Dust.

Against this background, the cluster is developing programmable materials with the focus topic production and upscaling of new methods. It takes into account all the concepts, wherein different programmable functional blocks can be skillfully integrated in structural components.

Research topic

The focus topic of “production and upscaling” deals with the development of production methods for programmable materials to produce them at a reasonable price and use them in components. First and foremost, the members of this research team consider materials that can be programmed with regard to their mechanical properties and can, for instance, perform a predefined shape change as a response to an external trigger.

The known basic principles regarding the shape change of materials such as auxetic, metastable or Miura structures serve as a starting point. On the basis of these, the researchers build structures which can perform a predefined shape change. Folded Miura structures can completely unfold, for instance, by means of a continuous movement in only one direction.

After selecting suitable materials for building these structures with respect to the function to be performed (e.g. high or low forces), the research of the technologies required for building the structure plays an important role because these need to be effectively ready for series production. The research cluster thereby considers not only additive production methods but also casting and embossing technologies.

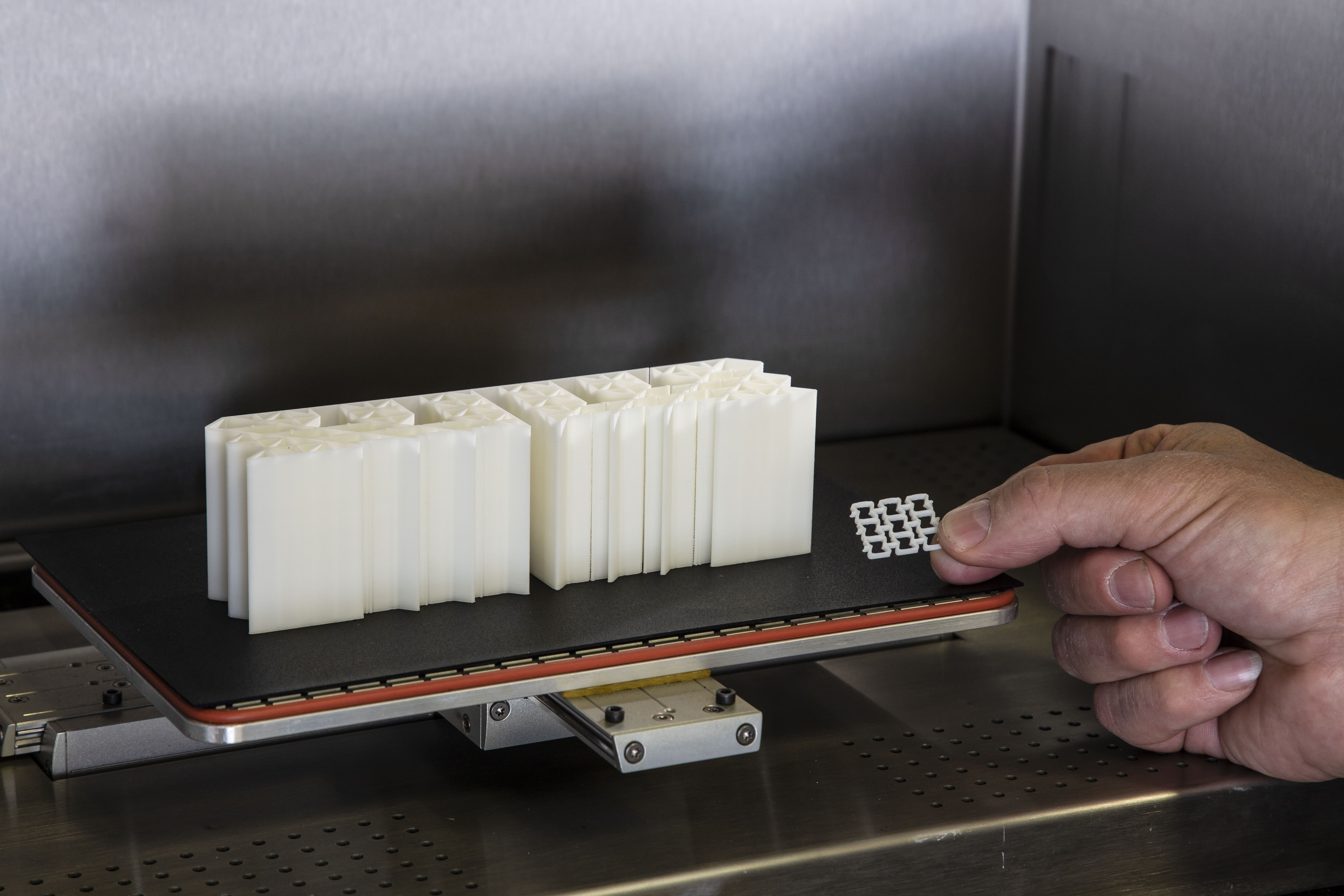

For components with high requirements for structural properties, the researchers would like to integrate programmable function modules through additive production processes. They are particularly suited for the formation of internal structures. For this purpose, 3D printers with high resolution are used in the cluster. Tried and tested structures are currently two way shape memory polymers, which can be programmed, for example, by defining high temperature and low temperature conditions and are thus interesting for ventilation scenarios.

There is a major problem for upscaling programmable materials manufactured with additive production processes: the functional unit cells from which the material is made require a very long time for printing. Therefore, many interesting components such as facade panels for the construction sector or front end support in the car are still too big for a realistic production with the existing processes.

The second pursued level of this research topic is combining the various functional and structural modules into one multi-functional structure. The challenge here is to find appropriate combining methods that ensure transfer of structural properties (e.g. stiffness) and functional properties (e.g. heat conduction) between different functional modules or between the functional module and the structure material. Both the approaches focus on the combination of functional and structural submodules and thus require additional process steps.

Especially regarding large quantities, partially semi-finished products are currently used to make the process chains as short and efficient as possible. Transfer to programmable components means that multi-functional semi-finished products whose functions are defined, i.e. programmed when manufacturing the component itself, are necessary. This can be the adaptation of the functional properties of a material (e.g. actuator or sensor function in Shape Memory Alloys, SMA), as well as the local introduction of certain functionalizations (e.g. functional area or structural area). The cluster should find solutions that provide an answer to how this programming can be achieved by means of local adaptation of process parameters (e.g. pressure, temperature) or by additional functionalization processes.

The cluster focuses on experimenting with the deep drawing of foils with integrated macroscopic functional structures such as Miura folds, among other things. The cluster wants to design a demonstrator with the stacked Miura-Ori-Films, which form Beul structures on the basis of bars and rods. The films then show a controllable deformation behavior with shape recoverability when unloading. For this purpose, acetone is glued onto the foils or connected at the ends by means of ultrasound welding and can thus be generated in a roll form on a kilometer scale. Its possible uses would include impact geometries, e.g. in car bumpers in the automobile sector.

Challenges

An important challenge for the focus of this topic is to achieve a functional and structural connection between the structural material and the functional module. The cluster is researching embedding the structures with the help of combining technologies, i.e. foaming, recasting and welding the structural elements with filling and matrix materials. Metamaterials should be recast or foamed such that their function remains guaranteed on the one hand while on the other, external signals or secondary factors no longer disintegrate the internal structure. Good results have been achieved so far via recasting the unit cells of the entire area with silicone. The benefit of silicone is that it can simultaneously perform a function in the system independently, i.e. control the feel or appearance and can help to coat the coarse structure.

In order to master the programmed structural changes, the researchers must also ensure a better understanding of the effect that the upscaling has on the physical parameters and of the dimensions in which the function can still be satisfactorily maintained.

To program the if-then relationships in the materials, the cluster also works on the expansion of the switchability and control functions of the materials. With the help of an elastic metamaterial in cubical form, the researchers would like to demonstrate how a ventilation flap can be implemented in automobiles by using programmable materials. The problem: controlling the opening of the outlet nozzle in the car functions according to the contact pressure of the airflow while the ventilation of the interior space is simultaneously temperature regulated accordingly for maximum comfort and is therefore not activated when the motor is cold. Here, for example, the participants attempt to apply additional framework conditions to the programmable material, e.g. motor temperature, by injecting conductive tracks or coated surfaces.

Another important aspect for the industrial production of programmable materials is durability control. Especially in the area of macroscopic elements that are brought together using the combining method, the joints are often a problem area, e.g. the seams of ultrasonically welded foils.

Future issues of the research topic production and upscaling include the consideration of other production technologies such as injection molding of programmable materials and integration of functional materials in conventional structures.

Status: 26.06.2019

Publications

Referred journals

Abel, Johannes; Mannschatz, Anne; Teuber, Robert; Müller, Bernhard; Al Noaimy, Omar; Riecker, Sebastian; Thielsch, Juliane; Matthey, Björn; Weißgräber, Thomas; Fused filament fabrication of NiTi components and hybridization with laser Powder bed fusion for filigree structures, Materials 14/16 (2021) Art. 4399, 18 pp.

Link

Participating institutes of the cluster: IFAM, IKTS, IWU

Gustmann, Tobias; Gutmann, Florian; Wenz, Franziska; Koch, Peter; Stelzer, Ralph; Drossel, Welf-Guntram; Korn, Hannes, Properties of a superelastic NiTi shape memory alloy using laser powder bed fusion and adaptive scanning strategies, Progress in Additive Manufacturing 5 (2020) 11-18

Link

Participating institutes of the cluster: IWU, EMI, IWM

Weisheit, Linda; Wenz, Franziska; Lichti, Tobias; Eckert, Medardus; Baumann, Sascha; Hübner, Christof; Eberl, Christoph; Andrä, Heiko, Domänenübergreifende Workflows zur effizienten Entwicklung Programmierbarer Materialien, ZWF Zeitschrift für wirtschaftlichen Fabrikbetrieb 115/7–8 (2020) 470-475

Link

Participating institutes of the cluster: IWU, IWM, ITWM, ICT

Conference proceedings

Kappe, Konstantin; Gustmann, Tobias; Gutmann, Florian; Stilz, Maximilian; Hoschke, Klaus

Metallic metamaterial with bistable behavior; in Proc. of 5th Fraunhofer Direct Digital Manufacturing Conference DDMC 2020; Müller, B. (Hrsg.) Fraunhofer-Verlag, Stuttgart (2020) 6 pp.

Lectures

Pretsch, Thorsten

Recognizing the Potential of 4D-Printing

2nd Edition of International Conference on Materials Science and Engineering Materials 2022

virtuell, USA; 28.03.2022-30.03.2022

Leichner, Alexander

A computational framework for the development of programmable materials based on unit cells and multiscale optimization

IX. International Conference on Coupled Problems in Science and Engineering 2021

virtuell, Chia Luga, Sardinien, Italien, 14.06.2021-16.06.2021

Leichner, Alexander

Optimal Design and Distribution of Unit Cells for Programmable Materials

14th Virtual Congress WCCM & ECCOMAS 2020

virtuell, Paris, Frankreich 11.01.2021-15.01.2021

Gustmann, Tobias

Fabrication and functional properties of additively manufactured NiTi lattice structures using adaptive scanning strategies

TMS 2020, 149th Annual Meeting & Exhibition 2020, co-located 9th International Symposium on Lead and Zinc Processsing PbZn 2020

San Diego, CA, USA; 23.02.2020-27.02.2020

Link

Gutmann, Florian

Eigenschaften von additiv gefertigten metallischen Metamaterialien aus einer superelastischen NiTi Formgedächtnislegierung

Fachtagung Werkstoffe und Additive Fertigung

Online-Konferenz, Potsdam, Deutschland; 13.05.2020-15.05.2020

Gutmann, Florian

Properties of additively manufactured metallic metamaterials using a superelastic NiTi shape memory alloy

Materials Science and Engineering Congress MSE 2020

Digital Conference, Deutschland; 22.09.2020-25.09.2020

Hübner, Christof

On the way to mass production of programmable and auxetic materials

Materials Science and Engineering Congress MSE 2020

Digital Conference, Deutschland; 22.09.2020-25.09.2020

Kappe, Konstantin

Metallic Metamaterial with bistable behavior

DDMC2020, Fraunhofer Direct Digital Manufacturing Conference

online, Deutschland; 23.06.2020-23.06.2020

Schwarz, Angela

On the way to mass production of unit-cell based auxetic materials

6th International Conference on Cellular Materials CellMat 2020

virtuell, Deutschland; 07.10.2020-09.10.2020

Schwarz, Angela

Wavy knits – enabling the production of auxetic materials

6th International Conference on Cellular Materials CellMat 2020

virtuell, Deutschland; 07.10.2020-09.10.2020

Gustmann, Tobias

Formgedächtnis - Ein Material, das zaubern kann. Das Potential einer spannenden Legierung

ZEREPRO Jahrestagung „3D-Druck in der Personalisierten Chirurgie - Option der Zukunft?“

Alte Handelsbörse Leipzig, Deutschland; 29.11.2019-29.11.2019

Link

Gustmann, Tobias

Nutzung punktgenauer Belichtungsstrategien für die Herstellung metallischer Metamaterialien aus superelastischem NiTi-Formgedächtnismaterial

TechnologyMountains iNNOVATION fORUM Medizintechnik 2019

Tuttlingen, Deutschland 24.10.2019

Link

Students' theses (Bachelor, Master, Diploma)

Fabrication and properties of additively manufactured Nitinol components for medical applications (M)

Fertigung und Bewertung auxetischer Metamaterialien im Hinblick auf Programmierbare Materialien (M)

Gewebe mit steuerbarer Strukturveränderung (B)

Herstellung eines bistabilen Metamaterials für die Entwicklung programmierbarer Materialien durch Thermoformen (B)

Konzeptentwicklung und Dimensionierung bistabiler Mechanismen für die additive Fertigung von metallischen Metamaterialien (M)

Konzeptentwicklung zur Implementierung von bistabilen Mechanismen in additiv gefertigten Gitterstrukturen (M)

Numerical investigation of flow-induced deformations of filter media (M)

Posters

Neumann, Christian

Control of functional groups on microcapsule/particle surface through novel coating approach

Jahrestreffen der ProcessNet-Fachgruppen Lebensmittelverfahrenstechnik, Mischvorgänge, Grenzflächenbestimmte

Systeme und Prozesse 2021

virtuell, Deutschland; 11.03.2021-12.03.2021

Schwarz, Angela

On the way to mass production of unit-cell based auxetic materials

6th International Conference on Cellular Materials CellMat 2020

virtuell, Deutschland 07.10.2020-09.10.2020

Schwarz, Angela

Wavy knits – enabling the production of auxetic materials

6th International Conference on Cellular Materials CellMat 2020

virtuell, Deutschland 07.10.2020-09.10.2020

Gustmann, Tobias

Nutzung punktgenauer Belichtungsstrategien für die Herstellung metallischer Metamaterialien aus NiTi-Formgedächtnismaterial

WerkstoffWoche 2019

Dresden, Deutschland; 18.09.2019-20.09.2019

Link